Chem Arrow was approached by a distinguished manufacturer known for its specialization in precision components serving a diverse range of globally expanding industries. Their reputation is well-established in the production of air conditioner and compressor shafts.

The Challenge:

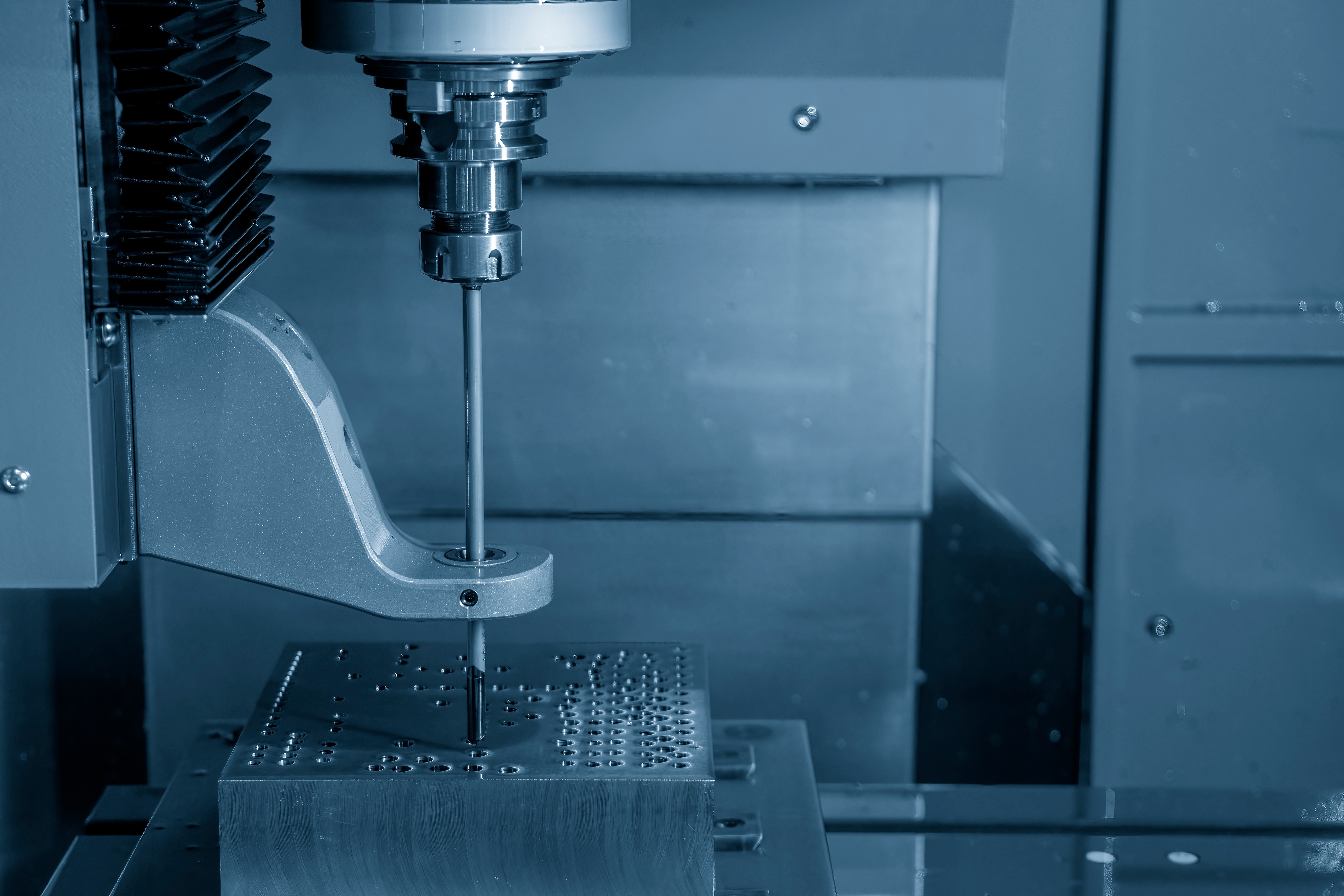

The customer faced a challenge common to many manufacturers: The need to improve tool life while working with demanding materials. In this case, the primary material being cut was AISI 1117 carbon steel (100%), and the operation involved gun drilling under high pressure conditions, with a coolant-through system using high-pressure (850 psi). Tool wear and chip evacuation presented notable concerns in their machining processes.

The Solution:

To address these challenges, the customer approached Chem Arrow for a solution. After a site visit from the area sales manager and distributor, the team recommended ArrowCool ME-349-LF, a high-performance coolant specifically formulated for demanding machining operations such as gun drilling applications.

The Results: The adoption of ArrrowCool ME-349-LF produced outstanding outcomes:

Extended Tool Life & Increased Productivity:

The application of ArrrowCool ME-349-LF extended the tool life significantly, increasing productivity from the current 400 pieces to an impressive 600 pieces. This 50% increase in productivity resulted in substantial savings, making the production process more cost-effective.

Improved Tool Wear:

The application of ArrrowCool ME-349-LF led to a noticeable reduction in tool wear. This improvement was evidenced by the production of smaller chips, which were easily evacuated from the drilling holes. The improved tool wear associated with running ME-349-LF resulted in an extraordinary 112.71% increase in tool life on this operation, underlining the product's effectiveness in enhancing tool longevity.

Customer Feedback:

The customer expressed high satisfaction with the demonstrated improvements and the extended tool life achieved through ArrrowCool ME-349-LF. As a result, they are now considering exploring other machining areas within their operations to achieve further cost savings and improvements in tool life.