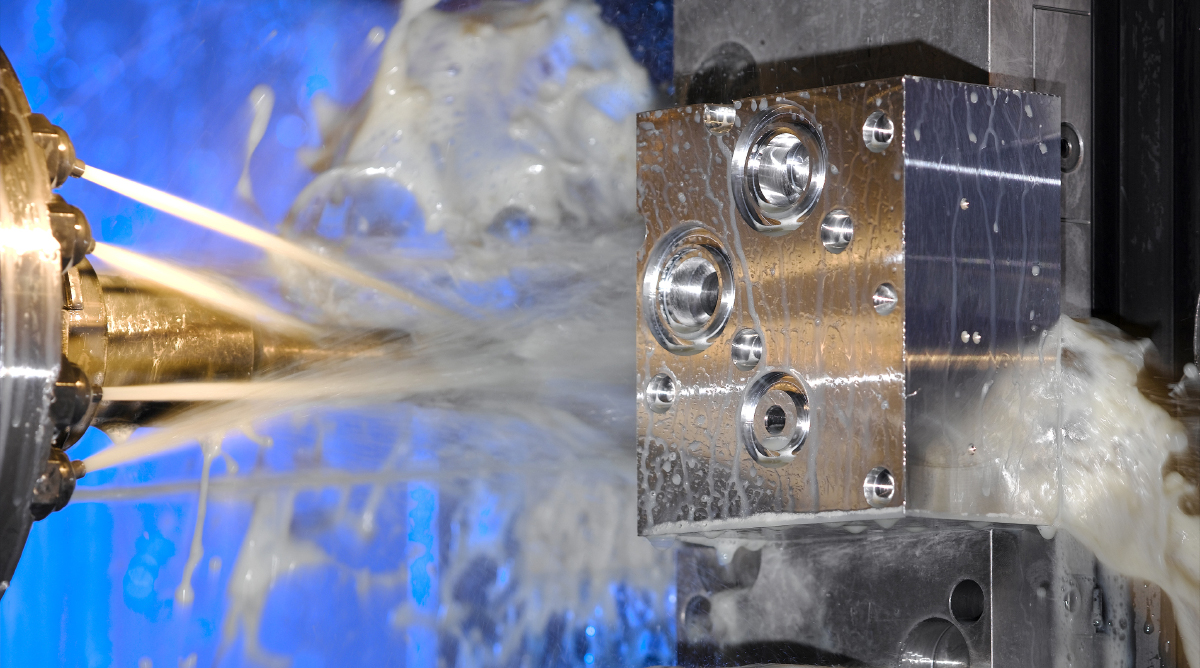

Extending the service life and performance of metalworking fluids is something most facilities strive to achieve. The correct management of metalworking fluids can contribute to:

- Reduced disposal costs.

- Decreased consumption of coolant concentrate.

- Eliminating costly biocides and other additives.

- Enhanced work environment for operators.

- Improved productivity through expanded machine uptime.

- Improved tool life and surface finish.

- Improved corrosion protection of parts and machine tools.

Commitment by management is one of the key components to improving the performance and ultimately reducing overall costs associated with metalworking fluids. Metalworking fluid makes up less than 1% of the operating cost, however, the impact of a poorly run program can have a detrimental effect on multiple areas of the business:

- Production

- Quality control

- Maintenance

- EHS

The following steps will enable you to take control and successfully manage the performance of your metalworking fluid:

- Start with premium fluid. Stable chemistry is the key to designing a program to optimize performance.

- Controlling concentration is one of the most important factors. 80% of all issues surrounding fluids can be directly related to concentration.

- Use an emulsion mixer (proportioner) to help dispense fluid properly.

- It is advisable to use treated water.

- Reduce and remove tramp oil.

- Top up machines with fresh coolant daily.

- Change your fluids as part of a routine maintenance schedule. We recommend: Arrow Clean

Working with your local supplier of metalworking fluid to develop a program that monitors all these vital areas will improve the performance of your fluid and reduce your overall fluid costs. Good suppliers often provide free laboratory analysis that tracks key indicators of fluid concentration, pH, bacteria and tramp oil. Understanding and monitoring these on a regular basis will ensure your fluid is kept in optimum condition. Proper fluid management is an investment in time but the long-term payoff is a trouble-free fluid that will optimize a variety of critical operations in your facility.

Chem Arrow offers FREE lab analysis and a new online coolant reporting system that allows you to maintain your fluids at maximized performance levels. Your Chem Arrow representative will work with you to provide complete satisfaction and optimum results. To find out more contact your local Chem Arrow representative or email sales@chemarrow.com